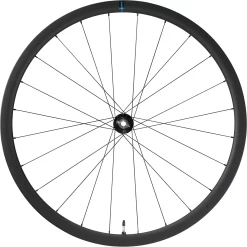

Fulcrum Speed 55 DB C19 Road Wheel Set 28" 12×100/12x142mm XDR 11/12-speed Disc CL Clincher TL Black

$97.99

- Discover a world of quality products.

- The Quality Choice for Smart Shoppers

- Multiple safe payment methods

- Uncompromising quality, every time.

The new rim profile characterizing the Speed 55 DB is a further step forwards in the search for the best aerodynamic performance. The model therefore focuses on a demanding and “racing” audience. To improve the rolling resistance (and ultimately the speed) of the wheel/tyre system, we designed this model in the 2-WAY FIT version.

The manufacturing process of the carbon fibre rim without holes in the internal channel – a patented construction technology – also allows a stronger and sturdier construction capable of withstanding even the most extreme racing conditions. The rim with a 19 mm inner width perfectly matches recent trends of using increasingly wider tyres – a choice that further improves the aerodynamic performance of the wheel/tyre system. This data has been validated by intensive wind tunnel studies and trials where new projects are tested on a regular basis. SPEED 55 DB proved to be the best option in terms of aerodynamic penetration indexes in the Fulcrum range and is derived from the profiles developed for the tubular version used by World Tour teams.

The SPEED range not only responds in terms of aerodynamic performance. Optimizing performance also requires the wheels to be light and run smooth. The scale stops at 1580 gr and we have chosen to add ceramic USB bearing components.

2-Way fit

Tubeless technology was first applied to the automotive sector, then to motorbikes and finally to cycle racing. After entering the MTB world, the moment has now come for its use on the road: And that’s what they offer you now! They have developed the 2-Way Fit technology to guarantee the perfect compatibility of tubeless rims also with normal clincher tyres and tubes. 2-Way Fit wheels are particularly versatile and therefore perfectly suited to any situation.

RDB Rim Dynamic Balance

The concept is simple and ingenious: balance the mass of the rim joint with an equal-value mass positioned exactly opposite.

USB – Ceramic Ultra Smooth Bearings

Fulcrum has always been respected for the extreme smoothness and reliability of its hubs.

These characteristics are due to the fact that all projects are developed in the R&D department and an almost manic attention is paid to every detail.

The hubs with USB (Ultra Smooth Bearings) ceramic bearings further increase the smoothness of the wheels and reduce weight and maintenance.

2:1 Two-To-One Spoke Ratio

At the moment the rider pedals at full power, the rotation of the sprocket set causes the spokes to yield at the freewheel, resulting in a loss of tension in the rim. This causes excessive bending of the whole and this inevitably means a loss of energy. Fulcrum has solved this classic problem in cycling with its patented 2:1 Two-to-One Spoke Ratio, that is, by doubling the number of spokes in the critical areas.

Anti-Rotation System

This new system takes the concept of the lacing system to a new level of performance.

Fulcrum’s technicians have redesigned the spokes and the hub shells to create a solid and solid unit. In this way, the spokes

a) they never lose their initial tension, keeping the wheel perfectly responsive and centred, and

b) that they remain in the position developed in the wind tunnel to ensure the best possible aerodynamics.

Cup & Cone

The cup & cone bearing differs from the classic cartridge bearings in that it works in perfect alignment with the corresponding forces, weight and thrusts coming from the frame, as the balls run on a groove positioned in direct opposition to these forces.

Be the first to review “Fulcrum Speed 55 DB C19 Road Wheel Set 28" 12×100/12x142mm XDR 11/12-speed Disc CL Clincher TL Black” Cancel reply

Related products

Road Front Wheels

Shimano WH-RS710 C32 Front Wheel 28" CL Disc 12x100mm E-Thru TL Black

Road Wheel Sets

Veltec Speed 6.0 Road Wheelset 60mm Disc Brake QR Shimano Black

Road Wheel Sets

Prime Primavera 32 Carbon Disc Wheelset 28" 10/11/12-speed Black

Reviews

There are no reviews yet.