Fulcrum Speed 40C Wheelset Road 28" Clincher Shimano USB Black

$96.99

- Discover a world of quality products.

- The Quality Choice for Smart Shoppers

- Multiple safe payment methods

- Uncompromising quality, every time.

Features technology used in pro tours. The maximum uphill, the maximum downhill – the Fulcrum Speed 40C is the current benchmark for wheels with medium-high rim profiles.

Momag

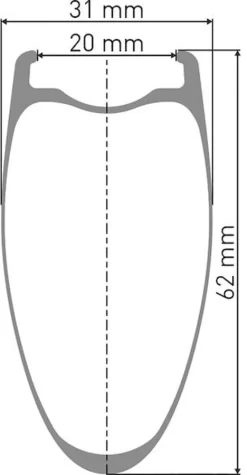

No drilling in the rim bed: this means a uniform rim throughout without critical points or breakages, and for clincher profiles no rim tape is necessary, which has a positive effect on the weight.

The advantages are immediately apparent: longer rim life, greater strength, the possibility of tightening the spokes and higher stiffness; in terms of performance, this means higher reactivity and better acceleration.

Anti-rotation system

Fulcrum engineers have redesigned the spokes and hub housings to create a strong and solid unit. This way, the spokes never lose their initial tension and the wheel remains responsive and perfectly centred. The spokes also remain in the position developed in the wind tunnel to ensure the best possible aerodynamics.

2:1 Two-To-One

At the moment when the rider pedals with full force, the rotation of the sprocket package causes the spokes on the freewheel to give way and the rim to lose tension. This causes an excessive bending of the whole wheel and inevitably means a loss of energy. Fulcrum has solved this classic problem with its patented Two-to-One Spoke Ratio, which doubles the number of spokes in critical areas.

USB ceramic bearings

The hubs with USB (Ultra Smooth Bearings) ceramic bearings further increase the smoothness of the wheels and reduce weight and maintenance.

Plasma freewheel

The plasma treatment makes the aluminium particularly hard and resistant to abrasion and surface wear. This made it possible to reduce material thicknesses to a minimum, all to the advantage of weight, while maintaining durability and reliability.

Details

- Brake surface with 3D diamond treatment for optimum braking force and dosing under all conditions

- contrary to the pictures the wheelset is delivered without grey decals !

Be the first to review “Fulcrum Speed 40C Wheelset Road 28" Clincher Shimano USB Black” Cancel reply

Related products

Road Wheel Sets

Veltec Speed 6.0 Road Wheelset 60mm Disc Brake QR Shimano Black

Road Front Wheels

Zipp 303 Firecrest Disc Front Wheel 27.5" 12x100mm SRAM/Shimano Road TLR Carbon Black

Road Front Wheels

Shimano Road WH-RS100-CL Wheel Front QR 100mm Rim Brake Black

Road Front Wheels

Road Front Wheels

Dt-swiss DT Swiss ARC 1400 Dicut Front Wheel 62mm 5x100mm QR

Reviews

There are no reviews yet.