Fulcrum Speed 40 DB C19 Road Wheel Set 28" 12×100/12x142mm HG 8-11-speed Disc CL Clincher TL Black

$96.99

- Discover a world of quality products.

- The Quality Choice for Smart Shoppers

- Multiple safe payment methods

- Uncompromising quality, every time.

SPEED is synonymous with competition and top performance – when only the stopwatch judges a road bike outing. It was developed for the World Tour pros who use the tubular tyre version and for all those who use these wheels for racing.

So what features should a SPEED non-tubular version have that is 40 mm high and therefore ideal for many situations?

That’s simple: the best of everything. That’s how SPEED 40 DB, 2-Way Fit (Tubeless) + Disc Brake was developed.

SPEED 40 DB is an impressive set of wheels for disc brakes, a state-of-the-art rim, with new shapes and technical concepts. Significantly wider at 26.5 mm, as well as featuring an aerodynamic shape with a pronounced 8 mm rim flange, it also has a “Carbontwill” texture that optimises the rim’s elastic response.

The aerodynamic profile has been thoroughly revised: from simulations with tests on prototypes to select the best design taking into account crosswinds and turbulence caused by the disc, to a thorough analysis to locate the best materials and combine them in this project.

Other clues to understand the soul of this wheel? These include: 2-Way Fit, so tubeless from the start, with a 19 mm wide channel. The bearings: USB, ceramic, cone & bearing shell. And, of course, the oversize flanges of the hubs to take full advantage of the disc brake.

SPEED 40 DB is definitely the best choice for those who have chosen disc brakes and are looking for maximum performance, with a competition pedigree and a medium profile that is perfect for most trails.

2-Way Fit

Tubeless technology was first applied to the automotive sector, then to motorbikes and finally to cycle racing. After entering the MTB world, the moment has now come for its use on the road: And that’s what they offer you now! They have developed the 2-Way Fit technology to guarantee the perfect compatibility of tubeless rims also with normal clincher tyres and tubes. 2-Way Fit wheels are particularly versatile and therefore perfectly suited to any situation.

RDB Rim dynamic Balance

The concept is simple and ingenious: balance the mass of the rim joint with an equal-value mass positioned exactly opposite.

USB – Ceramic Ultra Smooth Bearings

Fulcrum has always been respected for the extreme smoothness and reliability of its hubs. These characteristics are due to the fact that all projects are developed in the R&D department and an almost manic attention is paid to every detail. The hubs with USB (Ultra Smooth Bearings) ceramic bearings further increase the smoothness of the wheels and reduce weight and maintenance.

2:1 TWO-TO-ONE SPOKE RATIO – Disc Brake

At the moment the rider pedals at full power, the rotation of the sprocket set causes the spokes to yield at the freewheel, resulting in a loss of tension in the rim. This causes excessive bending of the whole and this inevitably means a loss of energy.

Fulcrum has solved this classic problem in cycling with its patent 2:1 Two-to-One Spoke Ratio, that is, by doubling the number of spokes in the critical areas.

MOMAG

What is MoMag? A magnet and a lot of expertise. This is how the patent of the tested “Mounting Magnet” system, i.e. MoMag, was born.

Anti-Rotation System

This new system takes the concept of the lacing system to a new level of performance.

Fulcrum’s technicians have redesigned the spokes and the hub shells to create a solid and solid unit. In this way, the spokes

a) they never lose their initial tension, keeping the wheel perfectly responsive and centred, and

b) that they remain in the position developed in the wind tunnel to ensure the best possible aerodynamics.

Rim Full Carbon Technology

Fulcrum Full Carbon rims are manufactured using combinations of different fibre typologies developed in the laboratory, including unidirectional and the well-known 3K at 90 degrees, which polishes the models at the top of the product range.

For their production, a special resin HTG (“High transition grade”) has been developed, which shows a glassy transition threshold at higher temperatures than any other fibre used in the bicycle industry. This enables unparalleled braking performance.

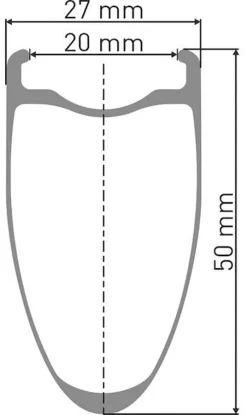

Wide Rim Tech

The Fulcrum R+D department, following the requests of the racing teams, worked to create rims with a greater width in relation to the past, starting from about 4 mm more than the previous ones. This technical choice makes it possible to offer the ideal support base for 25/28 mm tyres, the preferred sizes today. In this way, stability, optimal handling and high comfort are guaranteed.

Cup & Cone

The cup & cone bearing differs from the classic cartridge bearings in that it works in perfect alignment with the corresponding forces, weight and thrusts coming from the frame, since the balls run on a groove positioned in direct opposition to these forces.

Details

- Tyre width: from 23 – 50 mm

- Bearing type: USB ceramic bearings, adjustable cone bearings

Be the first to review “Fulcrum Speed 40 DB C19 Road Wheel Set 28" 12×100/12x142mm HG 8-11-speed Disc CL Clincher TL Black” Cancel reply

Related products

Road Front Wheels

Dt-swiss DT Swiss E 1800 Spline 23 Front Wheel 28" Disc CL 100/12mm Thru-Axle Black

Road Front Wheels

Road Front Wheels

Dt-swiss DT Swiss ARC 1400 Dicut Front Wheel 62mm 5x100mm QR

Road Front Wheels

Zipp 303 Firecrest Disc Front Wheel 27.5" 12x100mm SRAM/Shimano Road TLR Carbon Black

Reviews

There are no reviews yet.