Fulcrum Racing Zero Carbon C17 Road Wheel Set 28" HG 8-11-speed Clincher Black

$97.99

- Discover a world of quality products.

- The Quality Choice for Smart Shoppers

- Multiple safe payment methods

- Uncompromising quality, every time.

Its first appearance represented a groundbreaking innovation in the field of low-profile wheels. The innovation of the Racing Zero Carbon lies in its concept. Carbon and aluminium together to create a unique combination, creating a reinterpretation of the Racing Zero myth that is at the forefront of the range. There have always been accompanying comments such as “super stiff thanks to the aluminium spokes, super responsive thanks to the light rim”, you steer “as precisely as a razor blade” or “solid and comfortable, light and stable in the hectic moments of the race”.

What more is there to add? Nothing, except to improve this racing wheel with a new, even lighter, even more responsive and even stiffer rim.

The goal of Fulcrum’s R&D department was clear and perhaps banal: not to touch the character, but to improve the performance.

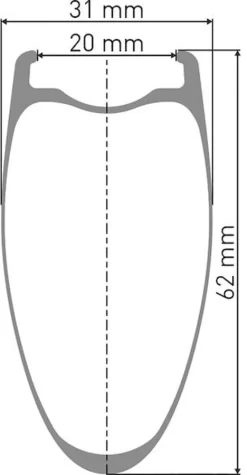

The basic dimensions of the new rim remain the same: 30 mm high, 17C channel that fits well with 25 mm clincher tyres. However, the material and the internal and external structure change. “Twill” carbon is used, while braking is improved with the new AC3 technology.

Racing Zero Carbon is a Racing Zero that runs faster, the most refined and innovative. It is the road bike wheel for the advanced marathon cyclist, the passionate rider who covers his kilometres in search of good times on the climbs, the right feeling and sporting satisfaction. For all those in search of the myth in its highest form of expression.

RDB Rim dynamic Balance

The concept is simple and ingenious: balance the mass of the rim joint with an equal-value mass positioned exactly opposite.

2:1 TWO-TO-ONE

At the moment the rider pedals at full power, the rotation of the sprocket set causes the spokes to yield at the freewheel with subsequent loss of tension in the rim. This causes excessive bending of the whole and this inevitably means a loss of energy.

Fulcrum has solved this classic problem in cycling with its patent 2:1 Two-to-One Spoke Ratio, that is, by doubling the number of spokes in the critical areas.

MOMAG

What is MoMag? A magnet and a lot of expertise. This is how the patent of the tested “Mounting Magnet” system, i.e. MoMag, was born.

Anti-Rotation System

This new system takes the concept of the lacing system to a new level of performance.

Fulcrum’s technicians have redesigned the spokes and the hub shells to create a solid and solid unit. In this way, the spokes

a) they never lose their initial tension, keeping the wheel perfectly responsive and centred, and

b) that they remain in the position developed in the wind tunnel to ensure the best possible aerodynamics.

F.I.C. Fulcrum Identification Card – 100% Handmade Quality

Fulcrum, since its creation, has been characterised by an approach that continues to this day: Design, prototyping and industrialisation of all wheels with the red “F”. Every single wheel component, the materials selected and the technologies used are the tangible result of the efforts Fulcrum makes every day to offer you the highest performance and reliability.

Wide Rim Tech

The Fulcrum R+D department, following the requests of the racing teams, worked to create rims with a greater width in relation to the past, starting from about 4 mm more than the previous ones. This technical choice makes it possible to offer the ideal support base for 25/28 mm tyres, the preferred sizes today. In this way, stability, optimal handling and high comfort are guaranteed.

Cup & Cone

The cup & cone bearing differs from the classic cartridge bearings in that it works in perfect alignment with the corresponding forces, weight and thrusts coming from the frame, since the balls run on a groove positioned in direct opposition to these forces.

Details

- Tyre width: from 25 mm to 50 mm

- Bearing type: USB ceramic bearings, adjustable cone bearings

Be the first to review “Fulcrum Racing Zero Carbon C17 Road Wheel Set 28" HG 8-11-speed Clincher Black” Cancel reply

Related products

Road Front Wheels

Road Front Wheels

Road Wheel Sets

Prime Primavera 32 Carbon Disc Wheelset 28" 10/11/12-speed Black

Reviews

There are no reviews yet.