Dt-swiss DT Swiss ARC 1100 Dicut 48 Rear Wheel Carbon 130/5mm Black

$96.99

- Discover a world of quality products.

- The Quality Choice for Smart Shoppers

- Multiple safe payment methods

- Uncompromising quality, every time.

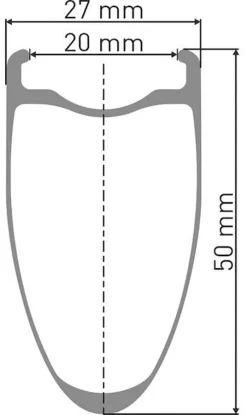

The ARC 1100 DICUT wheels are the perfect choice for those who like it really fast. Available in three different rim heights – 80, 62 & 48 mm – each in a rim brake and a disc brake variant, they leave nothing to be desired. Outstanding handling characteristics and minimal air resistance support the overall system of rider and bike. The high-quality DT Swiss components ensure absolute reliability and make the ARC 1100 DICUT wheels an ideal companion, both for 180 km long IRONMAN wheel tracks and for crisp 10 km time trials.

Ratchet System

The patented freewheel system with high-precision toothed pulleys guarantees maximum load capacity and reliability. Thanks to the no-tool concept, the system is very easy and quick to maintain.

Sinc Ceramic

It is the small details that make the difference and to which DT Swiss attaches great importance. SINC Ceramic ball bearings are based on exactly these details. Thanks to the optimisation of these details on DT Swiss wheels, you simply roll away from the field, your mates or your personal best time with a SINC upgrade. SINC ceramic ball bearings have been developed by DT Swiss as a system. They are based on balls made of the ceramic material silicon nitride (Si3N4) which is extremely resistant, wear and corrosion resistant. The bearing rings consist of a specially developed steel alloy adapted to the properties of the ceramic material and are precision ground. This combination reduces rolling resistance to an absolute minimum and ensures extended durability compared to conventional ball bearings. But not only the bearing itself is intended as a system. Only by adjusting the tolerances in the thousandth of a millimetre range, exactly matching the tolerances of the bearing seats of DT Swiss hubs, SINC Ceramic bearings develop their full performance and offer the decisive advantage over competitor products.

Pro Lock

In the Pro Lock process, a patented two-component adhesive is injected into the nipple thread, which enables the construction of extremely durable wheels. As soon as the nipples are screwed in, the adhesive is activated, which hardens completely at room temperature after approx. 6 – 7 hours. Multiple re-centering is possible without any problems, whereby the adhesive force decreases slightly with each re-centering.

Details

- ASTM Classification 1

- Freewheel system: Ratchet System 36 SL

Be the first to review “Dt-swiss DT Swiss ARC 1100 Dicut 48 Rear Wheel Carbon 130/5mm Black” Cancel reply

Related products

Road Wheel Sets

Prime Primavera 32 Carbon Disc Wheelset 28" 10/11/12-speed Black

Road Front Wheels

Road Front Wheels

Reviews

There are no reviews yet.